Laboratory

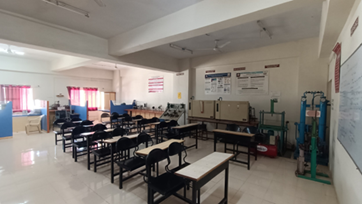

TFA Lab (PPE)

.png)

Description:

The Power Plant Laboratory is designed for B.Tech final year students to gain practical knowledge of power generation systems.

The lab is equipped with a Steam Power Plant setup that demonstrates the working principles of boilers, turbines, condensers,

and generators. Students perform experiments on energy conversion, efficiency analysis, and performance evaluation of thermal systems.

The facility provides hands-on exposure to real-world power plant operations, bridging theoretical concepts with industrial applications

in thermal engineering and energy systems.

Total Cost: ₹10,90,684/-

Total Area: 68 sq. m

Utility:

This lab is utilized for conducting practicals of Applied Thermodynamics and TFA-II.

It provides detailed information about basic components of Power Plants to students.

Lab Incharge:

Dr. J. A. Hole

Lab Assistant:

Mr. D. S. Khandagale

Turbo Machines Lab

Description:

The Turbo Machines Laboratory consists of modern experimental facilities for basic and applied research work in Rotodynamic Machines that add or consume energy.

It provides a platform for students to understand the fundamental concepts and principles of Turbo Machines through hands-on experimentation on various equipment.

Total Cost: ₹7,05,517/-

Total Area: 68 sq. m

Utility:

Practicals of Turbo Machines, Fluid Mechanics, and Fluid Machinery for both Mechanical and Civil Engineering students are performed in this lab.

Students gain knowledge of various types of rotating and fluid machinery through practical exposure.

Lab Incharge:

Dr. V. T. Tale

Lab Assistant:

Mr. K. A. Budhner

Thermodynamics / I.C. Engine Lab

Description:

The I.C. Engine Laboratory consists of five experimental setups, excluding student-fabricated projects.

It serves as a hub for UG, PG, and Ph.D. research activities, and many external students have also utilized this facility for their work.

This lab course is primarily offered to second-year B.E. Mechanical Engineering students to help them understand Internal Combustion Engines

and Air Compressors — including engine types, performance measurements, engine systems, pollutants, and compressor operation.

Total Cost: ₹28,84,515/-

Total Area: 68 sq. m

Utility:

This lab is mainly utilized for second-year undergraduate students studying Applied Thermodynamics.

Additionally, many postgraduate students and Ph.D. scholars use this lab for experimental and project-based research.

Lab Incharge:

Prof. K. B. Kawale / Prof. A. R. Devshette

Lab Assistant:

Mr. Amardeep Bajgule

Refrigeration and Air Conditioning Lab

Description:

The Refrigeration and Air Conditioning Laboratory (RAC Lab) houses four academic experimental setups — three from SP Engineers

and one from JP Techno Instruments — all of which are regularly calibrated.

One research project, titled “Performance Evaluation of A/C System by Using HPHX”, received a grant of ₹1,75,000/- from BCUD.

The lab showcases various important refrigeration components, along with their details such as working principles and manufacturing information.

Ongoing UG and PG research projects, including “Fabrication and Modification of Domestic Refrigerator by Using PCM”, are currently in progress,

with students applying for patents based on their work.

Total Cost: ₹4,43,435/-

Total Area: 68 sq. m

Utility:

This lab is utilized by Diploma, UG, PG students, and Ph.D. scholars for conducting practicals and research work.

It is used to demonstrate various test rigs essential for experiments in Refrigeration and Air Conditioning.

Lab Incharge:

Prof. J. A. Kute

Lab Assistant:

Mr. K. A. Budhner

Computer Graphics Lab

Description:

The Computer Graphics Laboratory is equipped with the latest modeling software that helps students understand 3D modeling and design concepts,

which play a vital role in Mechanical Engineering.

The lab provides hands-on experience with CREO software, enabling students to explore advanced Computer-Aided Design (CAD) techniques.

Additionally, the Computer Graphics Lab serves as a facility for Programming with Python, allowing students to enhance their programming and analytical skills.

Total Cost: ₹12,07,550/-

Total Area: 68 sq. m

Utility:

This lab is utilized by students to learn and practice CAD/CAM design and Programming with Python.

It provides a dual-purpose learning environment combining design visualization with coding fundamentals.

Lab Incharge:

Prof. P. L. Firke

Lab Assistant:

Mr. P. B. Kokate

Heat Transfer Lab

Description:

The Heat Transfer Laboratory consists of ten experimental setups, including student-fabricated projects.

This lab course is primarily offered to third-year B.E. Mechanical Engineering students to help them understand

the fundamental principles of heat transfer — including conduction, convection, radiation, boiling,

and condensation modes of heat transfer.

A research project titled “Analysis of Horizontal Rectangular Fin Array Dissipating Heat by Natural Convection”

received a grant of ₹75,000/- from BCUD.

Total Cost: ₹3,94,825/-

Total Area: 68 sq. m

Utility:

The Heat Transfer Lab is utilized for conducting practical sessions related to the Heat Transfer subject.

In addition, many research scholars use this lab to study and test different modes of heat transfer in various materials

under multiple experimental setups.

Lab Incharge:

Dr. P. S. Patil

Lab Assistant:

Mr. S. D. Sutar

Research Lab

Description:

The Research Laboratory is organized within the Mechanical Engineering Department to facilitate students’ research activities.

It is equipped with the latest software tools such as CREO, ANSYS, and SYSTAT,

enabling students to carry out advanced simulation and analytical studies for their projects and academic research work.

Total Cost: ₹8,43,945/-

Total Area: 68 sq. m

Utility:

Equipped with modern software tools, this lab is used by students to perform software-based analysis and modeling on platforms

like CREO, ANSYS, and SYSTAT. It serves as a key facility for computational and design-based research work.

Lab Incharge:

Prof. R. S. Sundge

Lab Assistant:

Mrs. Varada Bendre

CAD/CAM Lab

Description:

The CAD/CAM Laboratory is equipped with advanced software such as Pro-E (CREO), ANSYS, and Mastercam.

Pro-E is used for geometric modeling and drafting, ANSYS is a powerful finite element analysis (FEA) tool for structural and stress analysis,

and Mastercam is a computer-aided manufacturing (CAM) software used to generate CNC programs for lathe and milling operations.

All these software tools are installed and regularly used by students for academic and project-based learning.

Total Cost: ₹38,88,585/-

Total Area: 68 sq. m

Utility:

The CAD/CAM Lab is utilized for stress and deformation analysis using ANSYS software.

Mastercam software is employed for CNC lathe and milling module operations,

while students also use CREO, CATIA V6, and SOLIDWORKS for component modeling and design.

Lab Incharge:

Prof. R. S. Sundge

Lab Assistant:

Mrs. Varada Bendre

Mechatronics Lab

Description:

The Mechatronics Laboratory is established to provide an integrated learning platform for students in Mechanical, Electrical, Electronics, and Computer Engineering.

The lab is equipped with modern facilities such as Programmable Logic Controllers (PLCs), Microcontroller and Arduino Kits, LVDT, PID Controllers, and Data Acquisition Systems.

Total Cost: ₹7,60,353/-

Total Area: 68 sq. m

Utility:

This lab is utilized by Mechanical and Automation & Robotics students for practical experiments in automation, control systems, and sensors.

Mechatronics practicals include Pneumatic Trainer, Load Cell, Capacitive Level Trainer, Flow Measurement, and Optical Position Detector.

Lab Incharge:

Prof. M. M. Surwade

Lab Assistant:

Mr. K. A. Budhner

Theory of Machines (Design Lab-1)

.png)

Description:

The Theory of Machines (Design Lab-1) provides hands-on experience to students in understanding the principles, mechanisms, and dynamics of machines.

It serves as a bridge between theoretical concepts and practical applications, enabling students to visualize, analyze, and experiment with various machine elements and mechanisms used in real-world engineering systems.

Total Cost: ₹5,21,013/-

Total Area: 68 sq. m

Utility:

The lab is utilized for conducting practicals of the Theory of Machines subject.

Additionally, postgraduate students use this lab for analyzing different mechanisms, studying motion effects, and performing experiments with various setups.

Lab Incharge:

Dr. M. A. Ahire

Lab Assistant:

Mr. Amardeep Bajgule

Dynamics of Machinery Lab

Description:

The Dynamics of Machinery Laboratory is fully equipped with traditional and advanced equipment such as FFT Analyzer with four channels, Universal Vibration Test Rig, Gyroscope, Whirling of Shaft setup, and Balancing Machine to satisfy both technical needs and the university curriculum.

The laboratory received a research grant of ₹1,50,000/- from BCUD and generated revenue of ₹55,000/- by providing consultancy and facilities to various colleges and UG/PG students.

Total Cost: ₹10,47,993/-

Total Area: 68 sq. m

Utility:

This lab is well-equipped with working models, experimental setups, and demonstration kits.

It facilitates learning through interactive experiments and real-life applications, preparing students for industry requirements in areas such as machine design, automation, automotive, and robotics.

Lab Incharge:

Dr. P. R. Sonawane

Lab Assistant:

Mr. P. B. Kokate

Metallurgy and Material Science Lab

Description:

The Metallurgy and Material Science Lab provides hands-on experience with the fundamental properties and behaviors of engineering materials.

Students explore the structure, processing, and performance relationships of metals, polymers, ceramics, and composites.

Experiments include hardness testing, tensile strength measurements, heat treatment, and microstructure analysis, emphasizing data collection, analysis, and interpretation to understand material behavior.

Total Cost: ₹16,37,388/-

Total Area: 68 sq. m

Utility:

This lab is utilized by second-year students, postgraduate students, and Ph.D. scholars to learn and conduct practical experiments in Material Science and Metallurgy.

Lab Incharge:

Prof. O. G. Kulkarni

Lab Assistant:

Mr. P. B. Kokate

Workshop

Description:

The Workshop is fully equipped with traditional and advanced machines such as belt-and-pulley-driven manual and automatic lathe machines, universal milling machines, and different types of grinders.

A separate CNC section is available to impart knowledge about programmable automation and flexible manufacturing systems.

Basic manufacturing sections including carpentry, fitting, welding, plumbing, and blacksmithy are also part of the workshop.

Total Cost: ₹70,07,032/-

Total Area: 592 sq. m

Utility:

The workshop is utilized for performing practical activities by Mechanical Engineering students.

It is also used for repair, maintenance, and various manufacturing activities across the college.

Lab Incharge:

Prof. S. J. Jagtap

Lab Assistant:

Mr. Sandeep Sapkal

Hydraulics and Pneumatics / Industrial Fluid Power Lab

Description:

The Fluid Power System includes both hydraulic (hydra = water) and pneumatic (pneuma = air) systems.

The Industrial Fluid Power (IFP) Lab consists of a Hydraulic Trainer Kit, Pneumatic Trainer Kit, Pressure Relief Valve Test Rig, and Compressor.

The lab also houses a museum with various components of hydraulic and pneumatic systems.

Total Cost: ₹8,76,036/-

Total Area: 68 sq. m

Utility:

This lab is utilized by Diploma, UG, and PG students to perform experiments and learn about hydraulic and pneumatic circuits, their components, and working principles.

Lab Incharge:

Prof. A. R. Debshette

Lab Assistant:

Mr. K. A. Budhner

Centre of Excellence

Description:

The Centre of Excellence on Composite Materials at JSPM Rajarshi Shahu College of Engineering, Pune, serves as a hub for cutting-edge research and innovation in advanced materials.

Established to foster advancements in composite technology, the centre is equipped with state-of-the-art facilities to support comprehensive research and development.

Key infrastructure includes an Electrospinning Setup for producing nanoscale fibers, a Vacuum Assisted Resin Transfer Molding (VARTM) Setup for high-quality composite manufacturing, a Hot Press for thermal processing, and a Pin-on-Disc Apparatus for evaluating tribological properties.

These resources enable researchers to explore the full spectrum of composite material applications, from design optimization to performance testing.

Research Achievements:

The Centre of Excellence has showcased its expertise at several international conferences:

- ICMES-2024 (March 22-23, 2024, Aditya Engineering College, Andhra Pradesh): One paper awarded Best Paper.

- ICFAMEAD-2024 (October 4-5, 2024, Symbiosis Institute of Technology, Pune): Presented 10 papers, one received Best Paper Award.

- 1st ICMIT-2025 (Muzaffarpur Institute of Technology, Bihar): Presented over 15 papers.

Lab Incharge:

Dr. P. R. Sonawane

Lab Assistant:

N/A

Centre of Excellence (CNC Lab)

Description:

The CNC Lab within the Centre of Excellence is equipped with two CNC machines: a CNC Lathe and a CNC Milling Trainer.

This lab is primarily used for Manufacturing Technology practicals, CNC hands-on training, and project work by Supra, BaJa, Mechagrinics, and Cipher Club teams.

It provides practical experience for students in precision machining and automated manufacturing.

Utility:

- Hands-on training provided to approximately 450 students.

- 15 faculty members have completed CNC training.

- Six research projects have been conducted and published in the lab.

- Projects include CNC lathe and CNC milling applications.

Lab Incharge:

Prof. D. M. Kupade

Lab Assistants:

CNC Milling Trainer: Mr. Samarth Dhole

CNC Lathe Trainer: Mr. Sahil Chaurange